- Home

- AAC Production Line

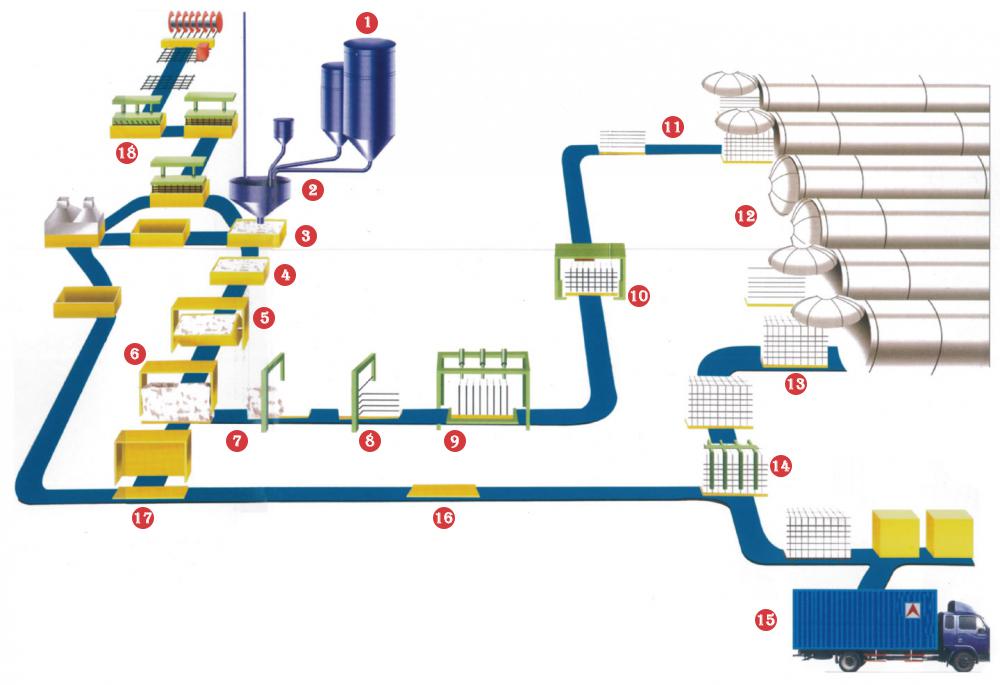

AAC Production Line

The fully automatic AAC production line is designed by SANKON based on more than ten years of research and experience. We can provide single machines to satisfy the different needs of customers as well as highly reliable production lines, which have been proven by hundreds of clients all over the world.

Annual Output 50 thousand m3-600 thousand m3

Material Type Sand AAC, Fly ash AAC

Higher Production Efficiency

The AAC production line developed by SANKON can achieve high automation. For example, processes like batching, pre-curing, overturning, grouping are full automatic and continuous. Currently, the highest capacity of the AAC production line we designed is 600 thousand m3 annually.

Flexible Automation

Theoretically, fully automatic production lines can optimize operating efficiency and minimize costs, thus becoming the highest economic benefit choice in the long run. But in practice, many details are negotiable to balance the cost and efficiency.

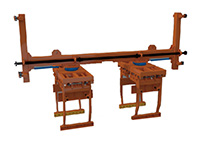

Forinstance, the travelling cranes and lifting appliances are positioned preliminarily in full automatic AAC production line. These travelling cranes and lifting appliances can move and stop automatically. However, for some clients, workers are very familiar with the working process. The desired results can be achieved and the cost of some related equipment can be saved if the travelling cranes and lifting appliances are manually controlled by the experienced workers.

Lower Labor Cost

The electrical control in AAC production line is achieved by Ethernet bus and PLC program. The processes from batching to finished product delivery are centralized controlled by section.

All operation are conducted on the control console fixed on the ground. Only 10 operators are needed for each shift. By adopting this AAC production line, working strength can be dramatically decreased, especially for those countries with high labor costs.

Safer Transportation

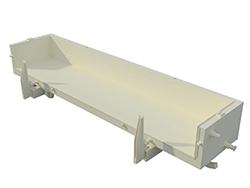

In the whole AAC production line, the mold and concrete blocks are transported by the transfer cart. Otherwise, the AAC production line is equipped with AAC packaging machine for automatic packaging. By this means, unnecessary high labor cost on transportation can be saved, and the risk of damaging the products during transportation can be avoided.